Filter nozzles are crucial in the elimination of contaminated thermoplastic material.

Failure to remove the contaminated material can lead to blocked feed holes which lowers production output and can also cause physical damage to the injection bushings.

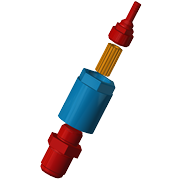

INJECTION POINT filtering system.

All filter components are fully interchangeable within the type. In this way we can meet the considerations for quality and cost with respect to new filter nozzles and maintenance. All filters are supplied with 240V heater band and thermocouple positioned at the rear body. They can be machined to suit any injection moulding machine. In case of using thermoplastic materials with glass or fibres they can be supplied with a titanium coated filter block and an internal removable hardened sleeve.

The new 2010’s FILTER has emerged, it’s right for high-pressure injection press

For further technical information contact our Design Department

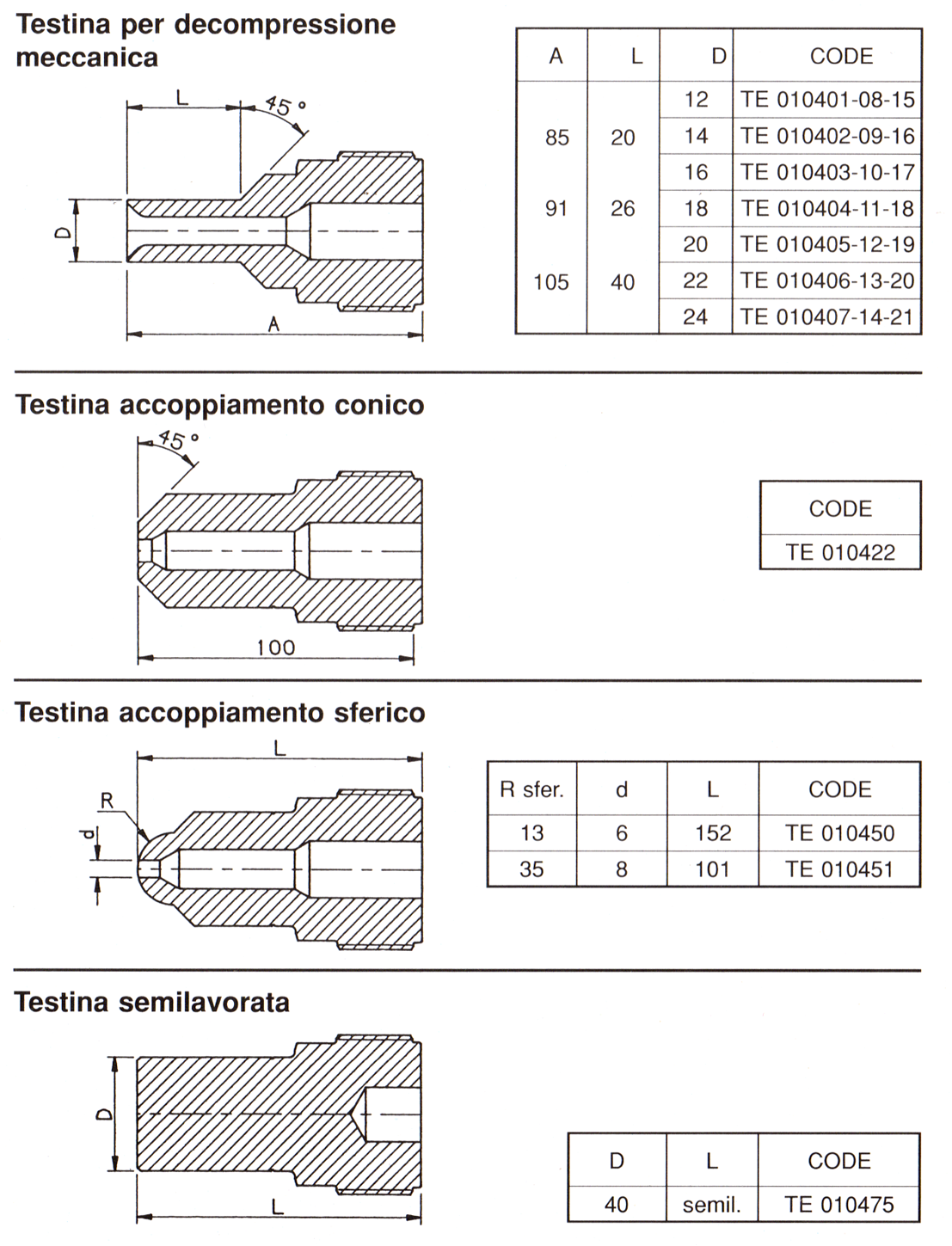

| TYPE | S | S1 | S2 | S3 | D1 | Ch1 | D2 | Ch2 | D3 | Ch3 | A | L | D | Ch4 | PASSAGGI |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IPF 300 | 161 | 16 | 67 | 100 | 60 | 52 | 45 | 36 | 68 | 60 | 60 | 20-40 | 10/12/16 | 27 | 0.2/0.3/0.5/0.8/1 |

| IPF 1000 | 197 | 20 | 88 | 113 | 80 | 70 | 56 | 50 | 75 | 65 | 70-90 | 20-40 | 10/12/16/20 | 36 | 0.2/0.3/0.5/0.8/1 |

| IPF 2000 | 245 | 25 | 123 | 125 | 100 | 90 | 75 | 65 | 85-105 | 20-40 | 12/16/20 | 41 | 0.3/0.5/0.8/1/1.5 |